All lateral flow assays need to produce robust and reproducible results. Ensuring this happens is ultimately the responsibility of the lateral flow assay manufacturer.

Abingdon Health has been manufacturing lateral flow assays for many years and has an extensive proven track record. In this article we outline how Abingdon Health approaches each contract manufacturing project.

Lay the foundations

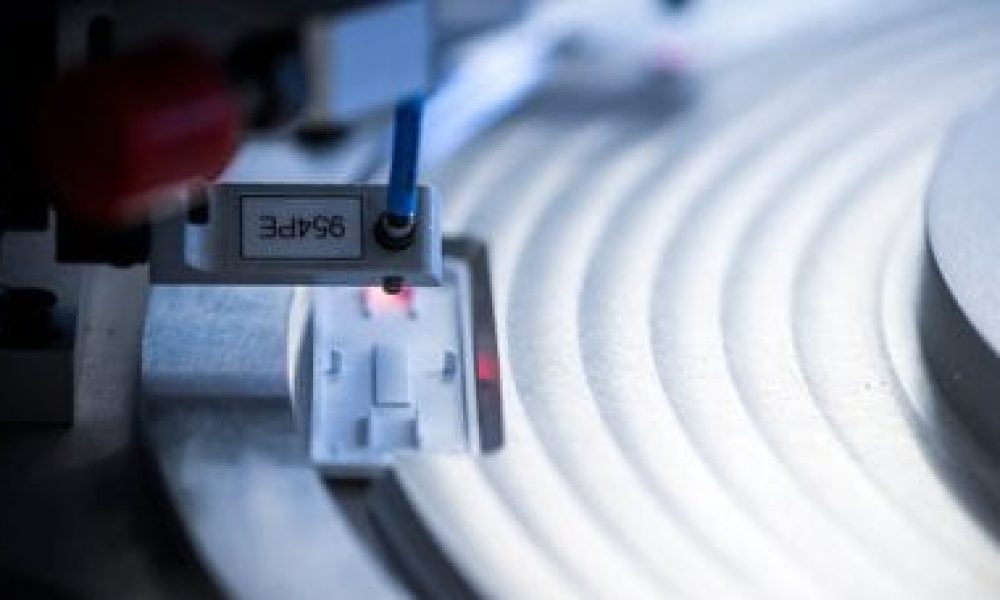

Each lateral flow assay is unique, assay scientists ensure the development and scaling-up processes are efficient and sustainable with large volume routine manufacturing being the end-goal. This is achieved by a combination of investment in expert personnel and equipment along with creating optimal processes and procedures.

Quality Standards

Abingdon Health has manufactured assays for a variety of industry sectors and Quality Management is an integral part of each assay manufacturing project.

Quality standards go hand-in-hand with manufacturing assays; implementing the right approach provides seamless transition through the various stages of assay development and through to routine test strip manufacturing.

Integrated approach

Each lateral flow assay is unique, some are quantitative, some are qualitative, some are multiplexed and different assays will require the use of different sample matrices. With this comes a variety of development and manufacturing challenges. Having integrated lateral flow assay and reader services can be the difference in the delivery of the optimal market-ready product.