Switching manufacturer could transform your business

A transformation that goes straight to the bottom line

Switching lateral flow manufacturer is the perfect opportunity to change the prospects of your business: a chance to engage with a partner with a fresh outlook or generate increased margin for your assay simply by changing your manufacturing partner.

Of course, there is a transfer process but the migration to a new manufacturer is certainly smoother when working with an outsourced manufacturing partner who has a successful recipe for transferring products using tried and tested processes and quality systems.

How to seamlessly switch to a new lateral flow manufacturer

Before changing to your new manufacturing partner, it is important to determine and remain focused on your key drivers for change.

• Are your manufacturing costs increasing and hindering your growth plans or profit?

• Can your existing manufacturer meet the future scale-up demand of your product?

• Is your manufacturer aligned with your ambitions and goals?

• Are they meeting your customer service expectations?

• Is your business core to their business and do they see you as a long-term supply partner?

If you are satisfied with your current manufacturing solution then there is no need to read on. However, if any of the questions above give you cause for concern, and you believe switching manufacturing partners may help improve the prospects of your business, then read on.

Here’s the approach!

• The first step of course involves identifying your potential new partner. At this point, it is always worth remembering the questions you need to answer – does the candidate have a scalable solution that can look after your product through its planned growth?

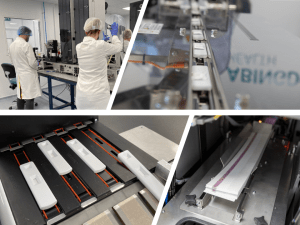

• Once you have shortlisted your specialist lateral flow manufacturer it is worth asking, do they have the right lateral flow pedigree? Also, can their in-house technical and manufacturing expertise ensure the production of consistent accurate lateral flow tests?

When you have your new manufacturing partners short-listed, you can take the next step.

• Approach your potential new partner for a consultation and quotation, this process should be free and under no obligation. The quote process should review assay specifications and manufacturing protocols and provide an opportunity to assess COG’s (Cost of Goods) reduction. This can be achieved through potential low risk material swap-out evaluation. There should also be an opportunity to identify the potential for continuous improvement in the lateral flow assay both in terms of performance and stability. The quote should also provide an option for a ‘like for like’ transfer.

• If you don’t have access to, or ownership of, your assay specification then your new provider should be able to give a considered assessment based on their experience. Abingdon Health’s expert technical transfer team for example offer such a solution. Contact us for more information on this provision.

• Mapping company and product goals with your new partner will allow them to devise a manufacturing solution, regulatory pathway and schedule, with appropriate batch sizes and clear timescales, that meet your growth plans.

• The final step includes the terms and timelines for the transfer plan can be completed, then it’s over to your new partner to make your vision a reality following a clear documented change management process.

The process outlined should ensure manufacturing transfer is as straightforward as possible, and addresses all quality control and regulatory considerations. Abingdon Health’s outsourcing guide explains how we successfully approach the technical transfer of rapid tests into routine manufacture in the millions. Giving new clients the option of commencing with a new manufacturing partner or simply offering a validated second source to an existing manufacturing arrangement.

Changing to a new manufacturing partner is all you need

The change process can appear daunting, but an experienced lateral flow manufacturer should be able to help you here. If not, then they may not be the right partner for you.

Your choice of lateral flow assay manufacturer can influence your ability to meet future demand, contribute to your brand success and increase your value through market share and profitability.

Your choice of lateral flow assay manufacturer can influence your ability to meet future demand, contribute to your brand success and increase your value through market share and profitability.

Perhaps now is the time to think about your existing relationship with your current partner, and ask yourself, ‘are we getting the most from the relationship?’

At Abingdon Health we thrive on helping diagnostic companies establish themselves and support their growth – Your journey, is our journey. If you’re looking to switch lateral flow manufacturer, or simply interested in what the process might entail and how could it help improve your position, please contact us to get a free, no obligation, assay transfer evaluation and manufacturing quotation.

Please call on +44 (0) 1904 406 050 or email [email protected] to discuss how can accommodate your rapid test in our lateral flow manufacturing facilities.

ACCESS OUR LATERAL FLOW MANUFACTURING EXPERTISE AND TECHNOLOGY TO ACHIEVE YOUR GOALS

Download our manufacturing brochure to learn how using our established supply chain and lateral flow manufacturing know-how can help you move faster, contain risks and embrace opportunity.