Second source lateral flow manufacturing

Meeting demand in the face of potential disruption

In situations such as the COVID-19 pandemic, lateral flow rapid diagnostics are in greater demand to respond to containment activities, widening screening programs and reducing the time to diagnosis. Therefore, it is important for manufacturers to be able to meet this challenge of getting assays to the point of need in a timely fashion. By using a second rapid test manufacturer’s automation and logistics infrastructure, you are able to project your manufacturing capability to a wider footprint while ensuring business continuity and order fulfilment.

In situations such as the COVID-19 pandemic, lateral flow rapid diagnostics are in greater demand to respond to containment activities, widening screening programs and reducing the time to diagnosis. Therefore, it is important for manufacturers to be able to meet this challenge of getting assays to the point of need in a timely fashion. By using a second rapid test manufacturer’s automation and logistics infrastructure, you are able to project your manufacturing capability to a wider footprint while ensuring business continuity and order fulfilment.

Working with you and your existing solution

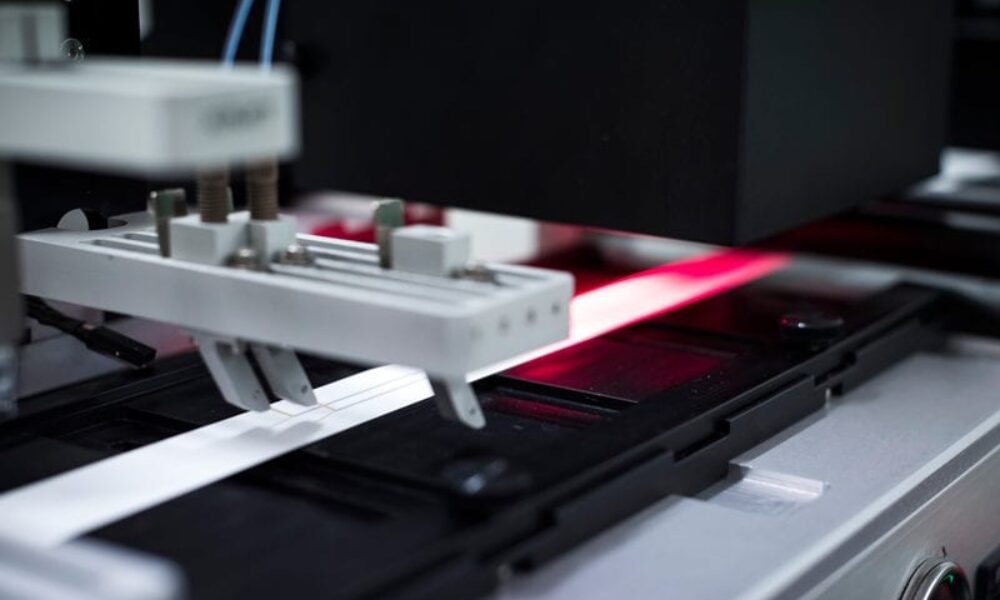

Abingdon Health is a collaborative partner and is comfortable working alongside existing primary supply solutions to ensure the continuity of supply of rapid tests. With automated and semi-automated manufacturing solutions we are able to ‘fast-track’ technical transfers into routine manufacturing, providing quick and easy short- and long-term solutions.

Working with a second manufacturer boosts output and market share and shouldn’t be dismissed because of perceived disruption. A good manufacturer should be able to manage the transfer process, leaving clients to focus on their strategy. Read our article about switching lateral flow manufacturer to understand how this can be done.

A de-risked approach with Abingdon Health

Abingdon Health’s primary manufacturing facility is located on the York Biotech Campus (formerly NAFIC) in York, UK. The site has a resilient infrastructure designed for all year round operation and has exceptional high-level safety and security in a GMP working environment. Our location provides exceptional off-shoring solutions to test manufacturers seeking to widen their global reach.

Abingdon Health’s primary manufacturing facility is located on the York Biotech Campus (formerly NAFIC) in York, UK. The site has a resilient infrastructure designed for all year round operation and has exceptional high-level safety and security in a GMP working environment. Our location provides exceptional off-shoring solutions to test manufacturers seeking to widen their global reach.

Our capabilities:

- Capacity to meet your manufacturing volumes

- Ability to work with primary manufacturers or in-house operations teams to support your inventory management

- Commercial and regulatory experience to support global market requirements

- Project managers to lead accelerated and fast track technical transfer

- Flexible solutions for card and strip manufacture through to producing assembled devices and kits.

- International logistics and flexible shipping solutions

Dual-site manufacturing

We also have another automated manufacturing facility in Doncaster, UK. Being able to produce millions of rapid tests across multiple sites allows us to offer supply chain security and fulfilment flexibility.

Contact a member of our team for a no obligation discussion about your project. We are happy to discuss a non-disclosure agreement (NDA) should you prefer.