Cost and supply benefits when partnering with a lateral flow test contract manufacturer

Outsourcing your lateral flow manufacturing is a practical solution to a range of problems such as securing supply chains or rationalising capital expenditure.

The COVID-19 pandemic has escalated demand for lateral flow tests placing more pressure on rapid test owners: the market is projected to reach USD 10.2 billion (marketsandmarkets.com). Whether rapid test owners are established or emerging, outsourcing is a strategy that can accelerate growth. Moreover, businesses who partner with a lateral flow test contract manufacturer find they can focus on staying competitive and identifying opportunities.

De-risking operational activities and costs

Many organisations’ first instinct maybe to increase in-house manufacturing capabilities for their new product(s). However, demands on a business can soon mount up and the burden can become acute when unforeseen events arise.

Outsourcing rapid test manufacturing alleviates pressure from a test owners or in-house manufacturers who operate at a low volume. Teams are free to concentrate efforts on developing the business through increased output and revenue. This can be achieved through:

- The development of new products.

- More time to identify opportunities in the market.

- Increased bandwidth to concentrate on the internal staff development and recruitment plans.

It is important for rapid test owners to protect cashflows while ensuring they maximise revenues. Outsourcing is an effective strategy for moving the capital off the balance sheet, without impacting your company’s ability to deliver on its business plan. Furthermore, outsourcing provides your company with the flexibility to increase production and respond quickly to spikes in demand.

Handing over the high costs of labour and equipment to your outsourcing partner can also save you time and money compared to manufacturing rapid tests in-house. In addition, removing operational and capital costs from the P&L can positively impact the total costs of goods sold (COGS) especially early on in a product’s lifecycle.

Employee turnover in life sciences can be high. Regardless of size, the threat to rapid test owners of employee departure is always there. There are risks associated when employees with specific knowledge move on. Not only are in-house operations negatively impacted in the short term, but there are also long-term risks when replacements are being recruited and trained. Potentially, capabilities are significantly diminished over time.

The manufacture of reliable and quality lateral flow tests requires specialist skills and equipment. A good lateral flow contract manufacturer builds breadth and depth across its workforce and is continually recruiting and developing their teams. By outsourcing, you are gaining quick and on-demand access to experienced and specialist staff.

Why partner with a lateral flow test contract manufacturer?

First and foremost, working with a contract manufacturer must be the right for your business and for securing your business’s future. Partnering with a dedicated lateral flow manufacturer should never be overlooked because of perceived disruptions to business continuity. The right manufacturer will guide you on the process, reduce disruption and carry any perceived burden: our article on switching to a new lateral flow manufacturer outlines how Abingdon Health manages the process.

Partnering with a rapid test manufacturer allows you to secure supply, irrespective of how complex an assay or market is. Abingdon Health achieves this by combing many years of experience with an established network of quality material suppliers that feed our multiple manufacturing sites.

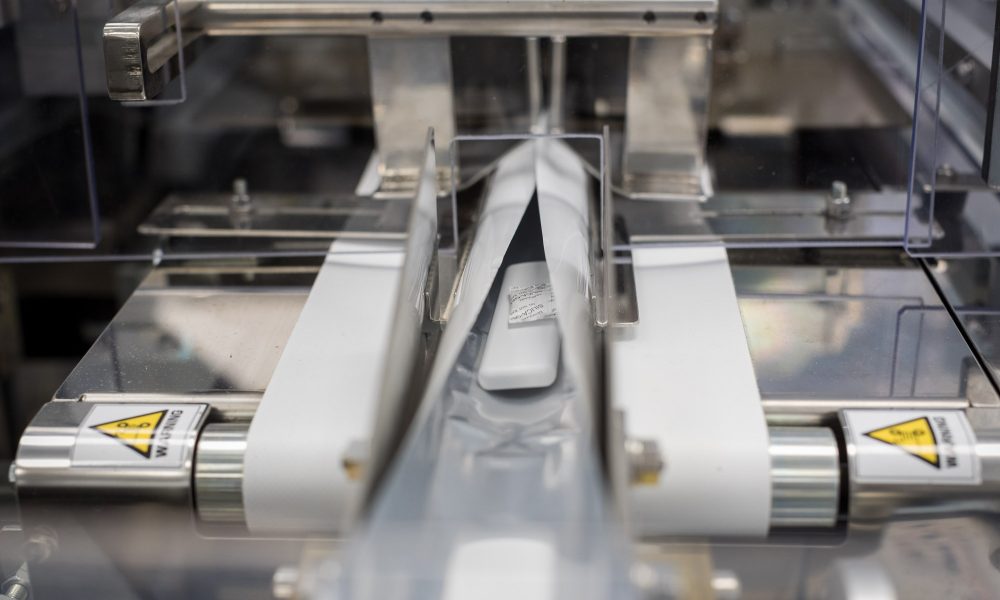

Outsourcing will give you access to multiple automated manufacturing lines that easily adapt to different assay formats and volumes. Meaning new product formats can transfer from R&D into routine manufacture while still meeting market demand for existing products. Also, access to precision automation with in-built quality control provides robust and consistent product supply.

Choosing the right partner for you

Outsourcing should provide the chance to boost innovation and competitiveness through a manufacturer’s in-depth experience, technical knowledge, and market insights. Thus, enabling you to identify new opportunities and adopt new technologies more quickly and profitably than competitors. The right outsourcing partner should feel like a safe pair of hands and be considered as an extension of your in-house team.

Abingdon Health is a global lateral flow test contract manufacturer who prides itself on being approachable and forming close, collaborative partnerships with customers. To find out how Abingdon Health can support your ambitions please contact us or alternatively download our guide on outsourcing vs insourcing.