GMP As A Cornerstone Of Lateral Flow Test Production

The Crucial Role of Good Manufacturing Practices in Lateral Flow Test Production

Understanding Lateral Flow Tests

The Foundation: GMP in Lateral Flow Test Design

Raw Materials and GMP Compliance

Manufacturing Processes: GMP as the Guiding Light

Quality Control and Assurance: GMP’s Final Frontier

Regulatory Compliance: GMP’s Gateway to Market Access

Key Takeaways

In this blog Abingdon’s Chief Operating Officer, Mark Jones, considers the importance of Good Manufacturing Practice (GMP) as a cornerstone of lateral flow test production; and why is should be a key consideration when you’re looking to outsource lateral flow manufacturing.

Abingdon Health’s team has vast experience in the lateral flow market and is a knowledge leader in the scale-up, transfer, manufacturing and regulatory approval of lateral flow products across a range of sectors. If you would like to understand more about the development, technical transfer, manufacturing and regulatory process and discuss any specific requirements don’t hesitate to contact Abingdon’s highly experienced team.

The Crucial Role of Good Manufacturing Practices in Lateral Flow Test Production

In the fast-paced landscape of diagnostics, lateral flow tests have emerged as a keystone for rapid and efficient disease detection. These tests, known for their simplicity and quick results, play a pivotal role in various industries, from healthcare to environmental monitoring. However, the reliability and accuracy of lateral flow tests hinges significantly on the adherence to GMPs throughout the production process.

Understanding Lateral Flow Tests

Lateral flow tests (LFTs), also known as lateral flow immunoassays, are diagnostic devices designed for the detection of specific analytes within a sample, often in the form of bodily fluids. These tests typically consist of a test strip – which incorporates various components such as a sample pad, conjugate pad, reaction membrane – and absorbent pad.

The effectiveness of LFTs lies in their ability to provide results within minutes without the need for specialised equipment or trained personnel. However, achieving this efficiency requires meticulous adherence to GMP principles at every stage of manufacturing.

The Foundation: GMP in Lateral Flow Test Design

The journey toward a reliable lateral flow test begins with the design phase. Incorporating GMP ensures that the materials chosen are of high quality, and the design considers factors such as specificity, sensitivity, and stability. GMP guidelines guide the selection of materials, from the substrate of the test strip to the reagents used in the assay.

The proper documentation of the design process is also crucial. GMP emphasises the creation and maintenance of detailed records, ensuring traceability and accountability. This meticulous documentation not only aids in troubleshooting, but also serves as a foundation for regulatory compliance.

Raw Materials and GMP Compliance

The significance of GMP extends to the sourcing and handling of raw materials. Manufacturers must carefully select suppliers who adhere to GMP standards in their own production processes. The integrity of raw materials directly influences the quality and consistency of the final product.

GMP practices mandate rigorous testing and validation of raw materials to guarantee their suitability for the intended purpose. This includes assessing the stability of reagents, verifying the quality of membranes, and ensuring that all components meet the required specifications. In any project, whether in development or in scale-up, Abingdon’s supply chain team are involved from the start to ensure that the raw materials selected are fit for purpose and offer scalability and robustness for the long-term.

Manufacturing Processes: GMP as the Guiding Light

Once the design and raw materials are in place, GMP takes centre stage in the manufacturing process.

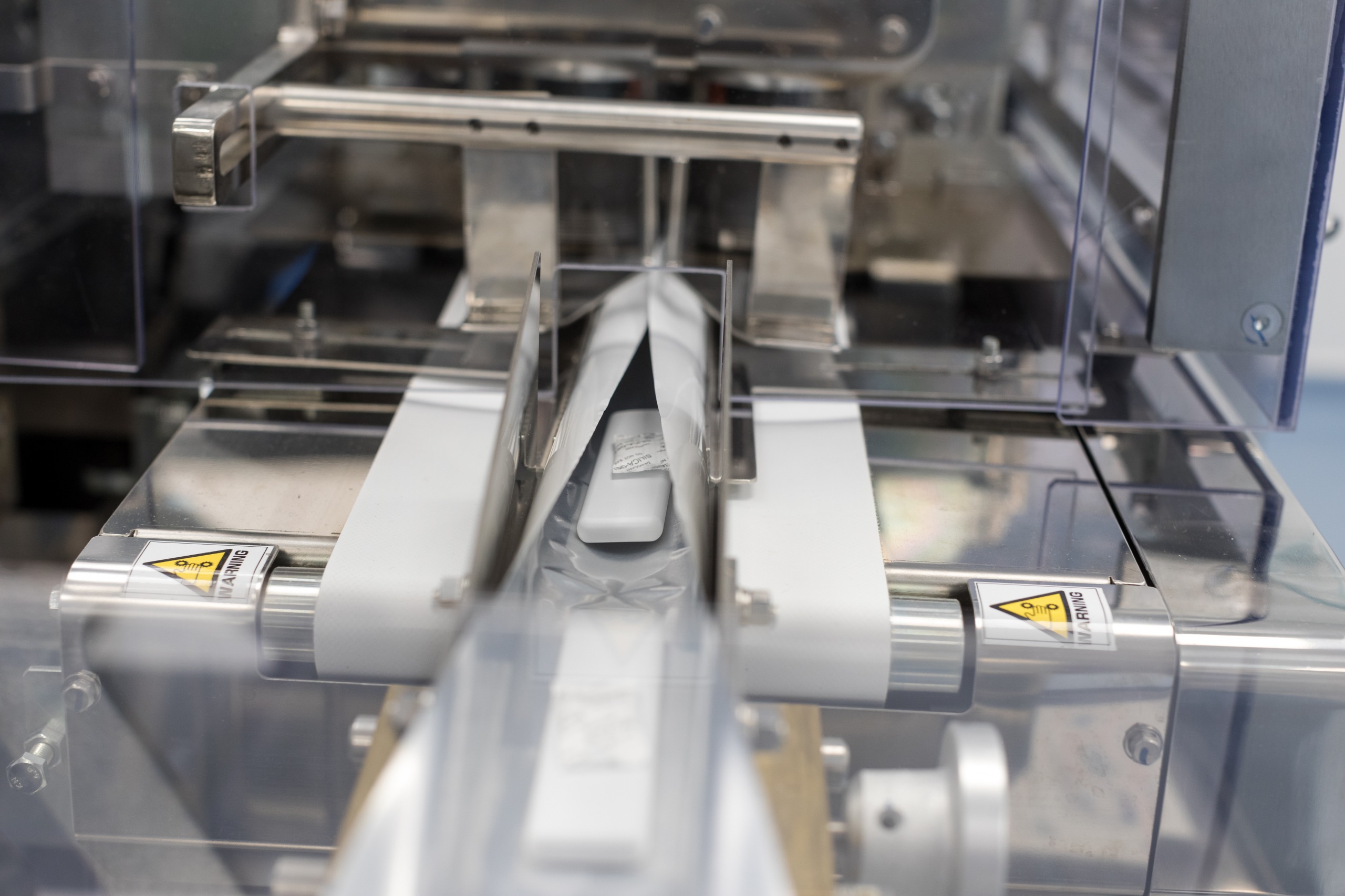

- The assembly of lateral flow tests demands precision and attention to detail. GMP principles guide the implementation of Standard Operating Procedures (SOPs) to maintain consistency across batches.

- Strict hygiene measures are also enforced, with a focus on minimising contamination risks. GMP ensures that manufacturing environments are controlled, monitored, and equipped with adequate facilities to prevent cross-contamination or errors that could compromise the quality of the tests.

- Regular training of personnel is another pillar of GMP in lateral flow test production. Ensuring that every individual involved in the manufacturing process is well-versed in GMP practices fosters a culture of quality and responsibility.

Quality Control and Assurance: GMP’s Final Frontier

The heart of Good Manufacturing Practice in lateral flow test production lies in the quality control and assurance processes. Every batch undergoes thorough testing and validation to ensure it meets predefined specifications. This includes assessing sensitivity, specificity, and reproducibility.

It cannot be underestimated how important the quality control and assurance process is. The materials used need to be robust and well characterised and the QC process itself needs to be fully validated and, importantly, well understood. Abingdon’s team places a great deal of focus on getting these elements right during the development and scale-up process.

GMP also mandates the implementation of in-process controls, providing real-time feedback during manufacturing. These controls serve as checkpoints, allowing for adjustments or corrections before a flawed batch progresses further down the production line.

Traceability is another critical aspect governed by GMP. Every lateral flow test must be traceable back to its raw materials, production date, and personnel involved. This not only facilitates recall procedures if necessary, but also enables continuous improvement based on historical data.

Regulatory Compliance: GMP’s Gateway to Market Access

In the realm of diagnostics, regulatory compliance is paramount. GMP serves as the gateway to meeting the stringent requirements set by regulatory bodies. Adhering to GMP not only ensures the safety and efficacy of LFTs, but also expedites the regulatory approval process.

Regulatory authorities, such as the Food and Drug Administration (FDA) and the European Medicines Agency (EMA), closely scrutinise manufacturing processes during product submissions. A robust GMP framework provides confidence to regulatory authorities during these assessments, paving the way for approval, market access and widespread adoption.

Key Takeaways

In the dynamic field of lateral flow test production, the role of Good Manufacturing Practices cannot be overstated. If you are considering outsourcing your lateral flow production, then adherence to GMP should be at the forefront of your considerations. From the initial design phase to the final quality control checks, GMP serves as the guiding force that ensures consistency, reliability, and regulatory compliance.

Abingdon considers GMP not as a set of rigid rules, but as a philosophy that underlines the commitment to producing high-quality lateral flow tests. By embracing GMP principles at every stage of the production process, we not only safeguard the integrity of the products, but also contribute to the overall trust and confidence in the manufacturing process. The importance of GMP in lateral flow test production cannot be ignored; it is the linchpin that ensures these tests deliver on their promise of reliability in the face of critical diagnostic challenges.

Decades of experience in taking tests from concept to commercialisation has led to Abingdon Health establishing effective processes that ensures efficient and cost-effective development, technical transfer and scale-up. Abingdon adheres to Good Manufacturing Practice to ensure tests are manufactured in a consistent and robust manner batch in, batch out. Contact the Abingdon team to see how we can help take your test from R&D into reliable manufacture and commercial success. Also, discuss our value-added services such as regulatory and commercial support that provides a de-risked and streamlined route to market.